An Introduction to the American Pocket Watch by Dave Coatsworth |

Perhaps you just came across your grandfather's pocket watch that had been tucked away in a drawer for many, many years. If your only experience with watches has been with modern quartz wrist watches, you may have questions about what it is, how it works and how to properly care for it. This article will attempt to answer some of the basic questions that you might have. Of course, we welcome you to bring your watch to one of our chapter meetings. Our members have a wide variety of knowledge when it comes to watches and clocks. It is almost certain that there will be someone at the meeting who can tell you more about your find! |

When you first look at a pocket watch, the most obvious component is the case. Generally speaking, the American pocket watch was sold in one of two types of cases: the open face case and the hunting case. The term open face is rather self explanatory in that it simply means that the face of the watch is open to viewing without opening a cover. An open face case is pictured below. |

|

While looking at this photo, let's cover some basic terminology. The ring at the top of the case is called the bow. This is where you would attach one end of a chain when wearing a pocket watch. Most bows are not fixed to the case and should pivot about the mounting points. This movement should be fairly stiff, however. (You can see in the photo that the bow stays upright on its own.) If the bow is loose, it may fall off of the pendant when the watch is worn. The knurled knob inside the bow is the crown. The crown is used to wind the watch and set the time. The shaft that the crown sits on is called the pendant. The glass over the face of the watch is the crystal. (If your crystal is made of plastic, you should consider having it replaced with a glass crystal as we now know that plastic crystals can accelerate oxidation of the steel parts.) The metal ring that holds the crystal is called the bezel. A hunting case pocket watch has a protective metal cover over the face (I suppose to protect the watch while the wearer engaged in rigorous activities, such as hunting). Inside the case, the watch is oriented so that the crown is at the '3' position. The front cover on the hunting case is opened by depressing the crown slightly. This will depress a latch to the point where the front cover can spring open. The front cover should open to approximately 90 degrees. If the lid opens farther than 90 degrees, a repair to the hinge may be necessary. If the lid does not spring open when the crown is pressed, a repair to the latch or the lift spring may be necessary. When you close a hunting case cover, do not simply snap it shut. Instead, depress the crown again to where the lid will clear the latch, then close the lid and release the crown. Simply snapping the lid closed will quickly wear the inside lip of the cover since the case metal is usually softer than the steel latch. A hunting case pocket watch is shown below. Often the design on the front and back covers are the same with the only difference being the cartouche. On the front cover, the cartouche was left blank so that the owner's initials could be engraved here. |

|

Note that you will sometimes see a watch in an open faced case where the pendant is located at the '3' position. This is sometimes called a sidewinder. In reality, it is simply a hunting case movement that has been recased in an open faced case. There is nothing rare or special about this configuration. In fact, it is undesireable to a collector as it indicates a non-original case and movement pairing. (As with all rules, there are exceptions. A watch buyer may very well have asked a jeweler to put a hunting case movement in an open face case, but this would have been rare.) Another interesting point about pocket watch cases is that, until fairly late in the evolution of the American pocket watch, the factory that made the watch movement did not put the watch in a case (and, usually, did not even make watch cases). Instead, watch manufacturers shipped completed movements to jewelers or distributors. Watch case manufacturers made a wide variety of cases available to jewelers. When someone bought a watch, they would first select the grade of watch movement they desired. Next, they would select a case and the jeweler would then case the watch for them. There is a mass-produced exception to this rule commonly referred to as the dollar watch which was produced by the millions around the turn of the century. However, for this article, we will restrict our discussion to the higher grade watches produced in America. Watch cases were made in a variety of metals. You can usually find out what type of metal your case is made out of by looking inside the back cover. Before we talk further about metals, let's talk about how to open the covers on your watch. Turn your watch so that you are looking at the side. In most watches, you will see two seams. These seams demark the 3 major components of the case. (If you do not see two seams, keep reading. There are exceptions and we will discuss them in a moment.) The middle part of the case, and the part that the pendant is attached to, is the body of the case. This is the part of the case that the watch movement is attached to. If you have an open faced watch, the front metal ring is the bezel. If you have a hunting case, the front part is the front cover or lid. The case back will be the part behind the watch body. Take a look at the seam between the body and the back. Is there a hinge somewhere on this seam? If so, then the back is hinged. Somewhere near the top, you will probably be a slight extended lip, as is shown in the photo at the right below. |

|

If the back is not too tight, you may be able to open it by pushing your fingernail in the seam between this lip and the case body. If you can not open the back cover with your fingernail, then you will need a case knife to open it. The blade on a case knife resembles that of a butter knife, so you may be able to substitute a suitable butter knife. The case knife is inserted into the seam between the lip and the case body and then given a slight twist. This should pop the cover open. Only do this if you are certain you can do it without damaging the case. Much of the watches' value may be in the case and you do not want to cause any damage to it. If you are the least bit uncertain of this, please take your watch to a professional watch repairer, or bring it to one of our chapter meetings, to find out how to open it without causing damage. It is also possible that, instead of a lip, you will see a slight separation in the seam somewhere opposite the hinge. As with the lip, this is where you would insert the case knife to open the cover. If there is no hinge and no lip/separation visible, then the case back probably screws on and off. (See the photo at the left, above.) You should be able to screw the cover off by placing the watch face-down in the palm of your left hand, placing the palm of your right hand over the back and then rotating your right hand counter-clockwise. The back may seem to be stuck, especially if the watch has been sitting for a long time in less than ideal conditions. Again, don't proceed if you are unsure of how to proceed. (And, whatever you do, don't use WD-40 to 'loosen things up'!) If the back does begin to unscrew, continue to unscrew it until you can lift it off. Once you have the back cover off, you may be able to see the watch movement or you may find yourself looking at another hinged cover. This second cover, if present, is called the cuvette. The cuvette will almost certainly be hinged and will have a slight separation somewhere opposite the hinge where a case knife can be inserted to open it. Occasionally, you may be pleasantly surprised to find a personalized inscription on the cuvette. When a watch was given as a gift and if the gift giver wanted to personalize or 'memorialize' that gift, they would do so with an inscription on the cuvette, as shown below. This was often done to mark a significant birthday or to recognize a milestone in years of service with a company. |

|

Another type of open face case that you might encounter is the swing out case. With this case, the watch movement is mounted to a hinged ring that swings out of the case back. The swing out case is shown in the photo below. This type of case almost always has a front bezel that screws on and off. To open this case, first remove the front bezel by unscrewing it. Now you will be able to see the hinge at the top of the swing out ring. You will also see a thumbnail cut-out at the bottom. Before proceeding, however, it is important to make sure the crown is in the 'set' position. (We will discuss this in detail later.) Even if this is a lever set watch, the crown will pull up a short distance. It is important to pull up the crown because the stem extends through the swing out ring. If you attempt to lift the ring out with the crown in the wind position, you can break the stem or other components of the winding mechanism. With the crown in the 'set' position, put your thumbnail in the thumbnail cutout and try to lift the ring. If it seems to catch after being lifted slightly, it may be hanging up on the stem. Turn the crown a bit while gently lifting to see if it releases. Do not force this. If it won't open, take your watch to a qualified watch repair person to see why it won't open. You can see the Swing Out Case in its various stages of opening in the photo below. |

|

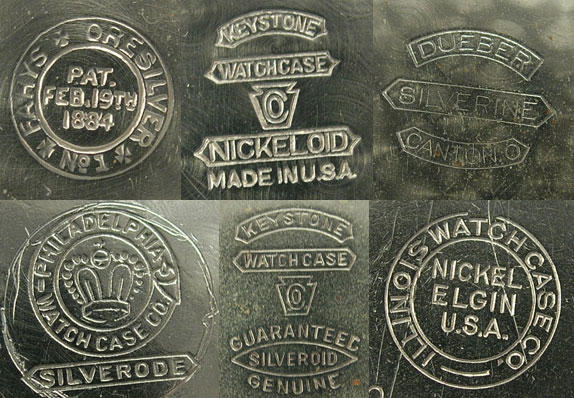

Now that we have the back cover and, if present, the cuvette cover open, we can determine what the watch case is made of. That information should be on the inside of either the back cover or cuvette cover. (Also note that you may see a serial number on the inside of one of these covers. This is not the watch's serial number. Remember how we discussed earlier that the watch and case were probably sold separately and then put together by the jeweler. The serial number on the case and that on the watch, which you will see on the movement itself, most likely have no relationship to each other.) There were typically four different compositions used for watch cases: nickel, silver, gold filled, and solid gold. Let's start with nickel. Nickel was the least expensive material at the time. It was given a number of different names by watch case makers to make it appear to be something that it wasn't. You will see names like silveroid, ore silver, silverine, silverode, Alaska silver, and, occasionally even nickel. Several of these case marks are shown below. |

|

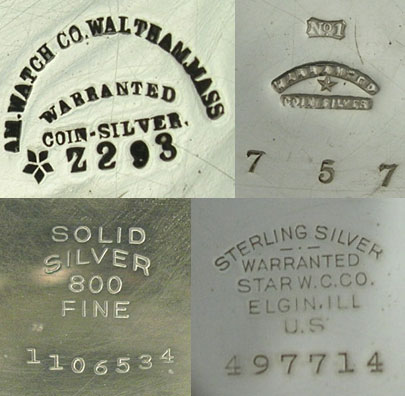

Next, we have cases that were actually made of silver. The most common marking you will see is COIN SILVER or sometimes simply COIN. In America, coin silver is usually 90% silver mixed with some other metal to add strength and wearability. You will also occasionally see STERLING, which is 92.5% silver. Less common in American cases (but more common in European cases) is .800 SILVER, which is 80% silver. Some silver case marks are shown below. |

|

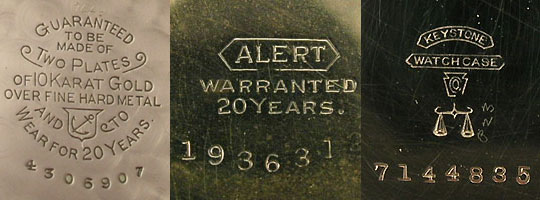

Next, we have gold filled cases. These are fairly common and often confuse people as to whether they are solid gold. Gold filled differs from gold plating in the process used. Gold filled metal is created by starting with a sandwich of metal in which the two slices of 'bread' are gold and the 'meat' is some less valuable metal - usually brass. This sandwich is repeatedly run through a roller press until the desired thickness of metal is achieved. You will rarely see the term 'gold filled' on a case. Instead, the usual tip-off that a case is gold filled is that there will be some indication that it is guaranteed to wear for a certain number of years. The number of years typically ranged between 5 and 25 years. The longer wearing cases would usually have a thicker layer of gold over the brass and, therefore, would indeed wear longer. (There is a certain bit of marketing going on here, just as there is today with some items like car batteries. You will sometimes see a case that is 'guaranteed to wear permanently'. There is probably no difference between this case and a 20-year case but it sounds better and the manufacturer is betting that, after 20 years, you won't even remember where you bought it!) Some of these gold filled marks are shown below. Note that the mark on the right doesn't say anything about metal content. This is a mark used by the Keystone Watch Case Company - one of the largest case manufacturers. The scales by themselves indicate that the case is a 20-year case. If there is a crown over the scales, then the case is a 25-year case. |

|

Gold filled cases do indeed wear if used for a long period of time. When the wear extends through the outer gold layer, the underlying brass is exposed. This is referred to as brassing. The photo below shows an example of brassing. The photo on the left was taken before the case was polished. It is very easy to see the brassing because of the patina the brass takes on when it has not been polished. On the right, you see the same case after polishing. It is now much more difficult to see the brassing. If your case does have brass showing, it can still be made quite presentable with a good polish. (Use a high quality, non-abrasive polish like Simichrome.) This also points out that one must be careful when buying a watch in a gold filled case in an online auction. If the case is nicely polished, you may not be able to see any brassing in the photos. |

|

Finally, we have solid gold cases. Perhaps surprisingly, these case marks are the most understated. Typically you will only see a 14K or 18K stamp along with the manufacturer's name. Sadly, a relatively small percentage of solid gold cases survive today - many having been melted down during the great depression and during other periods when the price of gold rose to high levels. Below is a typical solid gold case mark. |

|

Now, let's turn our attention to the watch movement itself. Below, you will see a few typical pocket watch movements from the late 1800's and early 1900's. There are a few things that you will almost always see stamped on American watch movements. We owe a great many thanks to early American watchmakers for putting serial numbers on all watch movements. It is through these serial numbers, and the factory records behind them, that we are able to easily determine quite a bit of information about any American pocket watch. You will also almost always see the number of jewels stamped on the movement. Of course, you will see the maker's name and the city and state where the factory is located. (There are 'Private Label' watches that are exceptions to this rule. If a particular jeweler ordered a sufficient quantity of watches, or paid a premium for them, the watch manufacturer would put their name, city and state one the movement and/or dial instead. This can make it a little more difficult to determine who actually made a particular watch.) You may also see the word ADJUSTED appear. |

|

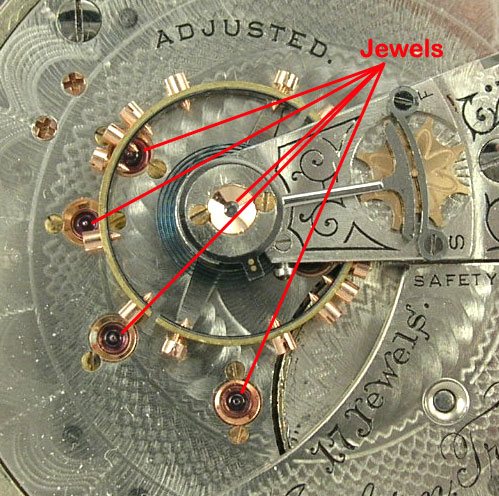

There are now several web sites where you can enter a watch's serial number and instantly get more information about a watch. Links to these sites are provided on our Links page. Jewels are used in better watches as bearings for surfaces which would otherwise experience wear over time. Generally, the higher the jewel count, the higher quality the watch. Of course, this also fell victim to marketing hype and we do see some watches with very high jewel counts, but where those jewels serve no real function other than to impress the buyer. You can see some of a watch's typical jewels in the photo below. In this case, the jewels are useful in that the pivots of the watch gears ride in the holes in these jewels. The result is very low friction and virtually no wear of the hole. Except in the highest grade watches, these jewels are usually either synthetic or industrial grade jewels and have virtually no value if removed from the watch. |

|

The word ADJUSTED or ADJUSTED TO x POSITIONS means that the watch has been adjusted by the watchmaker to time consistently and correctly in more positions that simply with the pendant in the upward position. Adjusting is a time consuming process and watches that were adjusted commanded a premium price. However, these watches were excellent timekeepers and were required for use on the railroads. If you've patiently read through to this point without actually trying to find out if your watch works, we commend you! So, without further ado, let's turn our attention to actually operating the watch. First of all, if you have just brought out a watch that has been sitting for many years, you should not use it on an ongoing basis without first having it serviced. After several years, the oil used to lubricate watches will dry, trapping any dirt that may be present. At this point, instead of lubricating, the oil has actually created something relatively close to sandpaper. A watch may very well run in this condition, but the pivots will wear much faster than normal. Finally, please resist the temptation to just add more oil or get out that WD-40 can. A watch in this condition must be completely disassembled, cleaned, then reassembled and oiled to operate properly and to ensure the watch's longevity. While you shouldn't run a watch continuously in an unserviced condition, it is certainly OK to see if it will run. The watch is powered by a mainspring, which is simply a piece of spring steel or alloy that is coiled inside a barrel. You wind up this spring by turning the crown in most American pocket watches produced since the 1870's. This is referred to as a stem wind watch. (We will discuss earlier watches in a moment.) Close any covers that you have opened while examining the watch. If you are looking down on the crown from above, you are going to turn it clockwise to wind the watch. Without applying too much pressure, try to turn the crown. One of three things is going to happen. In the normal case, the crown will turn but you will feel some resistance as the mainspring is wound up. Continue to turn the crown gently until you feel a noticeable increase in the resistance. At this point the watch is fully wound. If the watch is fairly clean, it may already be running at this point. If not, twist your wrist gently while holding the watch. This motion may be enough to start it. If it still does not start, there may be some other mechanical problem with the watch that is preventing it from running, or it may simply be too dirty. (If the previous watch repairer over-oiled the watch, that excess oil may have dried and bound the pivots in the jewels, preventing them from moving.) The second thing that may happen when you try to wind the watch is that you can continue to turn the crown with little or no resistance. In this case, either the mainspring (most likely) or something in the winding mechanism (less likely) is broken. This will need to be corrected by a watch repair person. The third thing that may happen is that you will not be able to wind the watch any further -- it is already fully wound. You will hear some people describe this condition as over wound, however this is not an accurate description of the real problem. The accurate description is that the watch is fully wound and that some other mechanical failure in the watch mechanism is preventing the watch from running. If you run into any of these problem cases, or are having trouble determining whether your watch will run, please bring it to one of our chapter meetings. While there might not be someone there who can fix your watch, there will most certainly be someone there who can show you how your watch should work and who will be happy to give you some honest information on what might be wrong with your watch. If nothing else, you will be better educated when you take your watch to a repair person. I mentioned earlier that there are some American pocket watches produced early in American watch making history that do not wind with the crown. These watches are referred to as keywind watches because they are wound with a key. A keywind watch is shown below. Notice that there is no crown. The pendant is rounded and its only function is to hold the bow. (In a keywind hunting case, there will be a push-button on the top of the pendant which is used to open the front cover.) |

|

The keywind watch is wound by opening the back cover and using a key with a square hole in the end to turn the winding square on the back of the watch movement. Keywind watch cases almost always have a cuvette. The cuvette will have a hole in it to provide access to the winding square. This hole allows the watch to be wound without exposing the entire watch movement to dust and dirt. The photos below show the key used to wind a keywind watch and the movement of an early American keywind watch. |

|

Since we are discussing the keywind watch and, since we are about to discuss setting the time on a pocket watch, let's start with setting the time on a keywind watch. If you look at the post that the hands are mounted to, you will notice that it is a square. You will also notice that this square post is the same size as the winding square.

You adjust the time by swinging open or removing the bezel, putting the key over this square and then turning clockwise until the correct time is set. Be careful that you do not slip when doing this as it is fairly easy to crack or scratch the dial. |

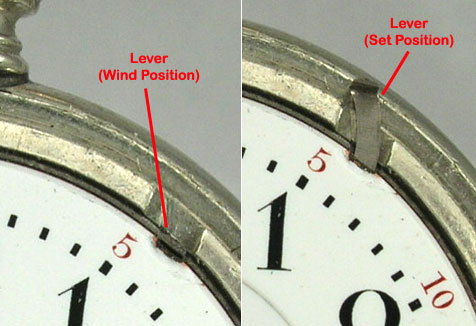

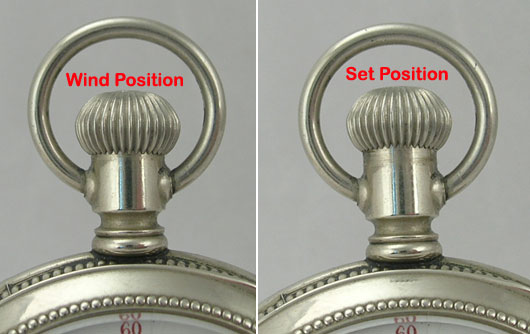

Now let's turn back to the stem wind watches and discuss how to set the time on these. There are 2 methods used in most American pocket watches. In both cases, the time is actually set by turning the crown either clockwise or counterclockwise. The difference is in how one enables the setting mode. To determine which method is used on your watch, first look just outside the edge of the dial between the '1' and '2' (or the '4' and '5' on a hunting case watch). You may need to remove the bezel to see this area. If you see the end of a small lever sticking out, as in the photo below, then you have what is known as a lever set watch. Lever setting was required at one time by railroad standards to prevent the operator from accidentally moving the hands while winding the watch. |

|

To set the time on a lever set watch, pull the lever out to the set position. Once fully extended, it should stay in the set position. (If you only pull it halfway out, it may spring back in.) Then, turn the crown to set the time. When the correct time has been set, push the lever back in to the wind position and replace the bezel. If your watch does not have a lever, then it is a pendant set watch. The watch is put into the setting mode by pulling up the pendant slightly. It should pull up somewhere between 1mm and 2mm, where it will click into position. (See the photo below.) At that point, turning the crown will move the hands and allow you to set the time. (If the watch still winds in this position, or seems to skip when setting the time, some adjustment may be necessary.) In both the lever and pendant setting watches, if you put the watch into the set position and it still winds, do not try to force the lever or crown further. There is a small spring under the dial which holds the setting mechanism in place when the lever or crown is pulled out to the setting position. It may be that this spring has broken and will need to be replaced by your watch repairer. |

|

If you have had your watch serviced, I would certainly encourage you to use your watch. (Of course, if it is a rare watch or if it is in like-new condition and you wish to preserve this condition, you may want to obtain a similar example that is more suitable to daily use.) First, take a moment to think about what you have. The watch you are holding may have been produced more than 100 years ago. It was probably used daily for many, many years before being put away in that drawer. Yet the watch will still keep near-perfect time if serviced properly. There were no laser cutting tools or computer-controlled NC machines in use when this watch was made. This watch was made with the cutting edge technology of the time. The watch factories had to invent many of the machines that were used to produce the components that went into the watch. Look at the precise fit and finish of the watch and marvel at the fact that it still works just as it did 100 or more years ago. If you wish to continue to use your watch on a regular basis, it should be serviced about every 3 years. You should also use a watch chain rather than keeping the watch loose in your pocket. One end of the chain attaches to the watch bow and the other can be clipped to a belt loop or some other part of your clothing. The chain will prevent you from accidentally dropping the watch, which could cause significant damage. |

|

If you wish to find out more about watches and the history of watch making, I would encourage you to join the National Association of Watch and Clock Collectors. You will find a link to the NAWCC site on our Links page. I would also once again encourage you to attend one of our chapter meetings if you live in the vicinity of Ventura County. There you will find a room full of people who love to discuss watches and clocks and who would be happy to tell you everything you want to know about your watch or clock. If you do not live in the Ventura County area, there is probably another NAWCC chapter in your area. Take a look at the NAWCC Chapter page to find a chapter near you. ©2007 Dave Coatsworth |